ELORA Torque Wrenches & Torque Laboratory

– Precision, Quality and Reliability

Correct use of a torque wrench

Torque wrenches can be found in every workshop. Especially in the fields of automotive, mechanical engineering and industry, reliable and high-quality torque wrenches are essential.

To protect the tool, the torque wrench should not be overloaded, otherwise it can be permanently damaged and the required accuracy is no longer achieved.

Maintenance of torque wrenches for longevity

ELORA torque wrenches are particularly durable. In order to benefit from this as long as possible, you should take good care of your tool.

After each use, for example, the triggering torque wrenches should be reset to the smallest adjustable value. This relieves the tension spring inside and prevents material fatigue. In addition, we recommend regular calibration.

Premium quality from ELORA

We always attach great importance to a particularly large product variety, which is why our torque wrenches are also available in different sizes. They are each specified for a specific torque range. You will find exactly the right torque wrench in the range from 0,7 Nm – 2800 Nm.

We work to the highest quality standards and with high-quality materials, so that our torque wrenches have a robust design, good workmanship and – depending on the model – fine-toothed ratchet heads.

They feature torque displays in different units of measurement and have a specific repeated accuracy.

The problem solvers: torque multipliers

In addition, we also offer torque multipliers, which are preserving nuts and bolts due to the constant transmission of force. In combination with ELORA torque wrenches, high, defined torques can also be applied to a screw connection. Our torque multipliers are compact, need low-maintenance and have long-term accuracy.

What is the difference between indicating and clicking torque wrenches?

Our large assortment offers the right tool for every situation. Both indicating and clicking torque wrenches have several advantages.

The clicking ones can be used as fixed or flexible and give a clearly audible “click” signal when the specified torque value is reached. The indicating types are easier to read due to their dial gauge or digital display and the risk of torque overload is minimized. They are therefore more accurate and offer a possibility of self-control.

The clicking ones, on the other hand, achieve a lower accuracy, since you may hold pressure after the “click” signal. Thus, the set value could be minimally exceeded. Depending on the model, our indicating torque wrenches are able to transmit the torque values to your computer.

ELORA Service: Calibration in our torque laboratory

If you want to use your torque wrench for a very long time, you should have it calibrated every 12 months or after 5000 load changes. Thereby the deviation of the torque setpoint from the actual value is determined, documented and readjusted in case of differences.

Our torque laboratory is equipped with state-of-the-art equipment. In addition, our experienced employees are trained to execute calibration in accordance with the DIN EN ISO 6789:2017 standard.

Torque wrenches from ELORA: Durable tools

With good care and regular calibration, our torque wrenches are a faithful companion for many years. Whether you work in an automotive workshop or in industry: we have the right torque wrench for you!

Torque Wrench, with vernier scale

2179

- for controlled torque application from 10 – 335 Nm

- main unit Nm with Nonius, secondary unit ft.lb.

- safe locking of the adjusted torque value by securing button at the handle end

- ELORA-No. 2179-S: exchanging the locking knob through the safety cap, the torque can be fixed tamper-resistant

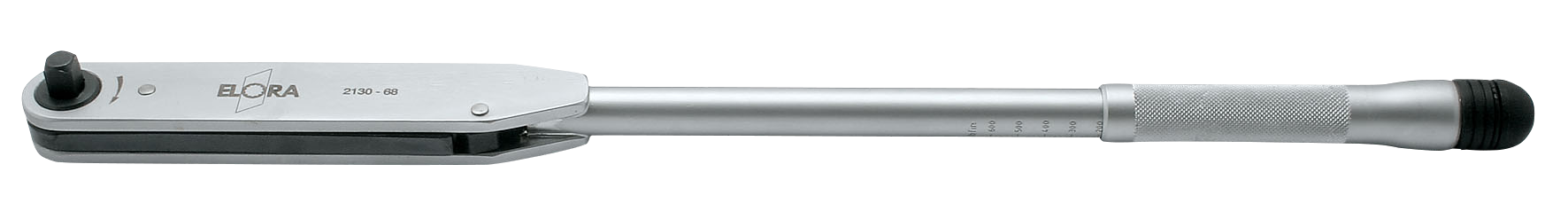

Torque Wrench

2130 – 2160

- for controlled torque application from 2,5 – 2000 Nm

- quad measurement scale for Nm, kgm, in-lb and ft-lb

- click type torque wrench with very noticeable and audible (‘click’) signal

- bi-directional fixing by turning the torque wrench

Elotronic Torque Wrenches 1/2"

2420

- indicating torque wrench for controlled tightening from 20 – 340 Nm

- measurement units: Nm, ft-lb or in-lb

- bi-directional fixing

- huge easy to read 4 digit numerical LCD Display

- audible buzzer and optical signal (3 bright LED´s)when target torque is reached

- 2 different measurement modes (Track Mode, Peak Hold)

ELORA on Social Media

You liked our article?

Follow us on Facebook & Instagram for more!

Contact

Questions? We are happy to advise you!

We look forward to receiving your message.